Upgrade your kiln with a reliable Evenheat controller designed for precision and ease of use. We carry the full range of Evenheat digital control systems, including TAP, Icon, and RampMaster models—each offering different features to suit your firing style. Whether you're a beginner looking for simplicity or a professional needing advanced programmability, you'll find the perfect controller for your Evenheat kiln here.

|

|

|

|

|

|

|

| FEATURES | TAP | ICON PLUS | Rampmaster II | Rampmaster III | ICON |

| Keypad | Touchscreen | Touchscreen | 24 key membrane switch | 24 key membrane switch | Touchscreen |

| No. of Thermocouples or Zones | 1 to 3 | 1 to 3 | 1 to 3 | 1 to 3 | 1 to 3 |

| Thermocouple Type | K, S, or R | K, S, or R | K, S, or R | K, S, or R | K, S or R |

| Method of Control | PID | PID | PID | PID | PID |

| Vary-Fire (Ramp/Hold) | Virtually unlimited Programs | Stores up to 12 user programs | Stores up to 6 programs (last fired program remains in memory) | Stores up to 6 programs (last fired program remains in memory) |

Store up to 30 custom user programs |

| Segments per program (each segment has a ramp rate to a temperature, and a soak period) | Virtually unlimited segments | Up to 32 segments per program. | 8 (can combine User programs 5 and 6 to get a 16 segment program) | 8 (can combine User programs 5 and 6 to get a 16 segment program) | Up to 32 segments per program |

| Skip-Step (move from one segment to the next ramp) |

Yes | Yes | Yes | Yes | Yes |

| Add Time (to current hold period) | Yes | Yes | No | Yes | No |

| Preset Cone Fire Programs | Yes | 4 Speeds (Slow, Medium Slow, Medium. Fast) | 4 Speeds (Slow Bisque, Fast Bisque, Slow Glaze, Fast Glaze) | 3 Speeds (Slow, Medium, Fast) | 3 Speeds (Slow, Medium, Fast) |

| Cone Fire to Ramp Hold | Yes | Yes | Yes | No | Yes |

| Temperature Scale | °F or °C | °F or °C | °F or °C | °F or °C | °F or °C |

| Multi Zone Control | Yes | Yes | Yes | Yes | No |

| Delay Start | Yes | Yes | Yes | Yes | |

| Alarm | Yes | Yes | Yes | Yes | Yes |

| Error Codes | Yes | Yes | Yes | Yes | Yes |

| Cost of Firing Calculation | Yes | Yes | No | No | Yes |

| Diagnostics | Yes | Yes | Yes | Yes | No |

| Wi-Fi Ready | Yes (via Wifi Accessory) | Yes | No | No | Yes |

| Wi-Fi enabled for easy software updating |

Yes (via Wifi Accessory) | Yes | No | No | Yes |

| Data Graphing | Yes | Yes | No | No | Yes |

| Monitor Firing with Phone App | Yes | Yes | No | No | Yes |

TAP Control

The TAP control has established itself as Evenheat's premier temperature control. From its easy to use touchscreen layout to its phenomenal solid state control ability the TAP excels at all levels. The TAP was very well received when we introduced it in 2016 and has proven itself ever since. The defining feature of the TAP Controller is the touchscreen design that offers a large screen and visual ease. The TAP Controller allows the choice of using pre-loaded firing schedules (glass and ceramic) or creating your own custom firing schedules.

The TAP Controller utilizes a Proportional Integral-Derivative (PID) control algorithm to ensure accurate schedule following with the fastest response, minimal overshoot, and limited steady state error. We couple that with our special limits, low error thermocouple components for excellent control performance.

Evenheat worked closely with SDS Industries to develop software designed specifically for use with our Quiet Drive Solid State Relay System. Temperature control decisions are made in fractions of a second with the solid state relay following along effortlessly. We highly recommend pairing the TAP with our Quiet Drive Solid State Relay System.

Features

This controller will make firing kilns just a little bit easier in these ways:

*touch-screen technology for the user interface

*easy-to-follow screen prompts

*graphical display of the firing process right at the controller

*Store virtually unlimited number of user programs

*also a virtually unlimited number of segments per program

*Ability to make adjustment during a firing such as add segments, add temperature, and skip segments

*Built in diagnostics testing

*Alarm

*Error Codes

*WiFi enabled for easy software updating and monitoring (via usb wifi add-on

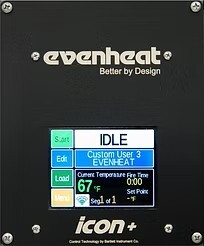

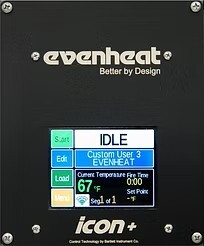

Icon+/ Genesis

The Icon+ starts with Bartlett's well-regarded Genesis platform and adds low-error, Special Limits thermocouples for incredible precision. We also fit the Icon+ with a non-metallic faceplate for exceptional Wi-Fi reception for the Bartlett mobile App. These added features take the Icon+/Genesis to a performance level found nowhere else.

Programming and use is easy and straight-foward. Performance is legendary and shines even brighter when paired with our Quiet Drive Solid State relay system.

The Icon+ represents the ultimate combination of Bartlett control prowess and Evenheat design to offer the highest performing Genesis based control available.

The Genesis control will work with our Quiet Drive Solid State Relay System.

Features

This controller will make firing kilns just a little bit easier in these ways:

*touch-screen technology for the user interface

*easy-to-follow screen descriptions

*different user-interface levels, which can be set to match the user’s firing knowledge

*graphical display of the firing process right at the controller

*Store up to 12 custom user programs

*Up to 32 segments per program

*Ability to make adjustment during a firing such as add segments, add temperature, and skip segments

*Built in diagnostics testing for use with a current sensor

*Alarm

*Error Codes

*WiFi enabled for easy software updating

*Register your Genesis on Bartlett web site or mobile app for remote monitoring of your kiln

Rampmaster II

The Rampmaster II is custom made for Evenheat by Bartlett Instrument Company. Has improved the reliability, features and ease-of-use to make Bartlett Instrument Company's kiln controllers the most accepted on the market. With the Rampmaster II cone-fire method, you select 1 of the 4 firing speeds and your cone number and you're firing your ceramics with as few as 6 key presses! The vary-fire method gives you the freedom to create up to six, 8-step user programs to fire your ceramics, crystalline glazes, glass or jewelry. Other features include delay start, preheat, alarm, cone adjustments, thermocouple adjustments, °F or °C operation, 16 segment program, and skip step. Advanced features of the Rampmaster II include 3-zone control!

Features

24-key membrane switch keypad

Selectable # of Zones (or Thermocouples), from 1 to 3

PID control algorithm

Can store up to 6 Ramp/Hold programs (last fired program remains in memory)

8 Segments per program (each segment has a ramp rate to a temperature, and a soak period) , with an option to combine User programs 5 and 6 to get a 16 segment program

Ability to "Skip-Step" (move from one segment to the next ramp)

4 speeds of Preset Conefire Programs , Slow Bisque, Fast Bisque, Slow Glaze, Fast Glaze

Ability to perform a ConeFire to RampHold firing

Ability to perform a delayed start of the kiln

Alarm

Error Codes

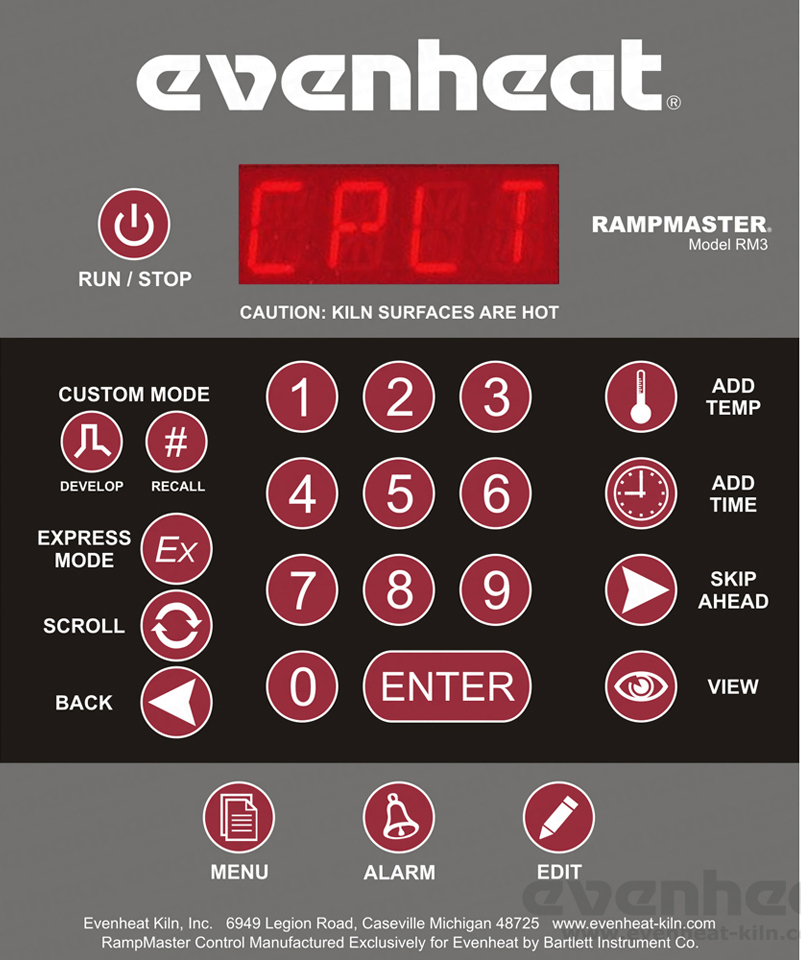

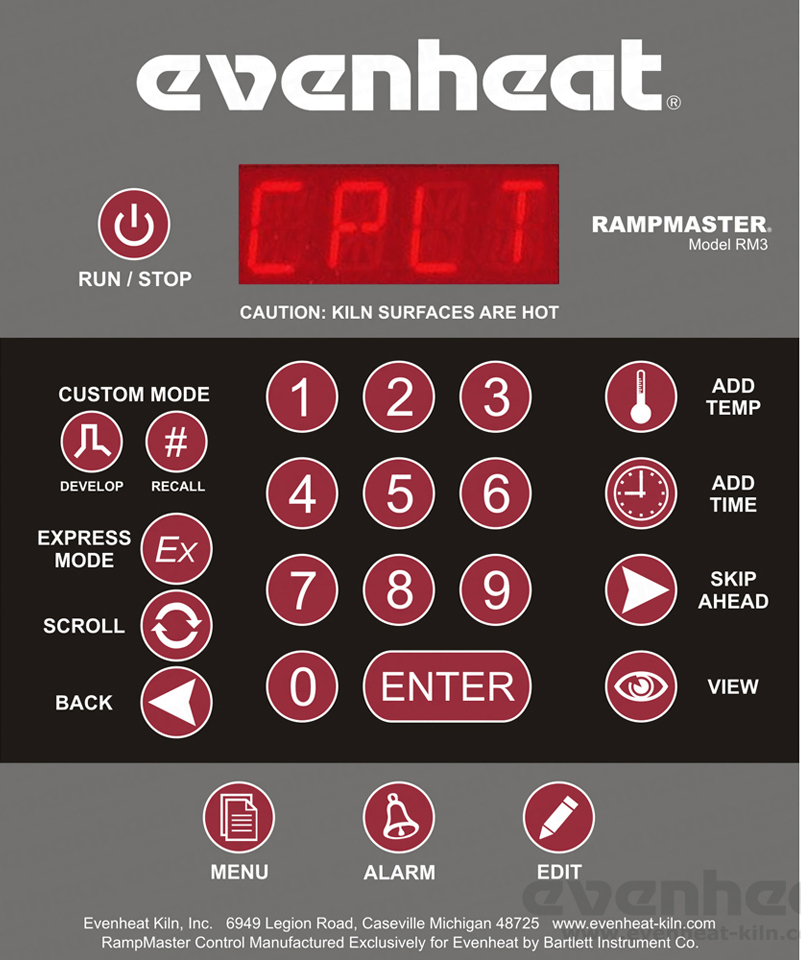

Rampmaster III

The Rampmaster is preferred by many for heat treating as it allows up to 12 custom user programs, numerical keypad and alarm features not found on our Set-Pro control.

The Rampmaster 3 is our traditional full featured control and features a 4 digit display. It offers two programming methods depending on your needs and experience: Custom Mode and Express Mode. Custom Mode is a programming method that allows you to define all aspects of the firing from temperature rates to set points and hold times. This programming style is perfect for heat treating and custom glass firing programs. Custom Mode offers full artistic control. Express Mode is a programming method designed exclusively for glass work and offers an easy, 3 step programming process. Simply key in your glass COE, firing style and firing speed to create the firing program. It's quick, it's easy and it's accurate.

The Rampmaster 3 control will work with our Quiet Drive Solid State Relay System.

Features

24-key membrane switch keypad

Selectable # of Zones (or Thermocouples), from 1 to 3

PID control algorithm

Can store up to 6 Ramp/Hold programs (last fired program remains in memory)

8 Segments per program (each segment has a ramp rate to a temperature, and a soak period) , with an option to combine User programs 5 and 6 to get a 16 segment program

Ability to "Skip-Step" (move from one segment to the next ramp)

3 speeds of Preset Glass Programs , Slow, Medium, Fast

Alarm

Error Codes

Icon

The Icon control is based on Bartlett Instruments Spark platform and is fitted with special limits thermocouples for precise temperature sensing and non-metallic faceplates for excellent Wi-Fi reception for the Bartlett mobile App.

The LT's were designed and tested in 2023 with the help of numerous independent/beta testing sites. These folks were given free-reign to modify the Icon control software and hardware to meet their standards of high performance at low temperature. They nailed it and we implemented their recommendations.

The Icon is built around Bartlett's new Spark platform and brings touchscreen design to the market at a lower price point.

It should be noted that all beta evaluation, testing and modifications were performed on LT's with Quiet Drive Solid State relay configurations only.

The Icon / Spark was rigorously field-tested by Bartlett, Evenheat and others over the latter course of 2023. Programming was found to be clean and simple. User interaction with the display was deemed excellent. As expected our Quiet Drive Solid State relay system performed beautifully.

As with all Evenheat control designs, the Icon adds to an existing control platform with improvements like low-error Special Limits thermocouples for precise temperature sensing and non-metallic faceplates for excellent Wi-Fi reception for the Bartlett mobile App.

The Icon brings outstanding performance and value to the marketplace.

For detailed information on the Icon (Spark) and mobile App visit Bartlett Instruments at bartinstrument.com.

Features

- Touch-screen technology for the user interface

- Easy-to-follow screen descriptions

- Different user-interface levels, which can be set to match the user’s firing knowledge

- Graphical display of the firing process right at the controller

- Store up to 30 custom user programs

- Up to 32 segments per program

- Ability to make adjustment during a firing such as add time to a current hold and skip segments

- Built in diagnostics testing

- End of Firing Alarm

- Error Codes

- WiFi enabled for easy software updating

- Register your Spark on our website or mobile app for remote monitoring of your kiln

- Use for 1 thermocouple or 1 zone kilns only

|

|

|

|