When most people talk about knives, they focus on the blade—its steel, grind, or sharpness. But as any experienced knifemaker knows, a knife is only as good as its handle. The shape of a handle affects balance, comfort, control, and safety. Whether you're just getting into knifemaking or you're refining your own designs, knowing the most common handle shapes—and why they matter—can make a big difference.

Let’s break down the key knife handle shapes, how they work in the hand, and when to use them in your builds.

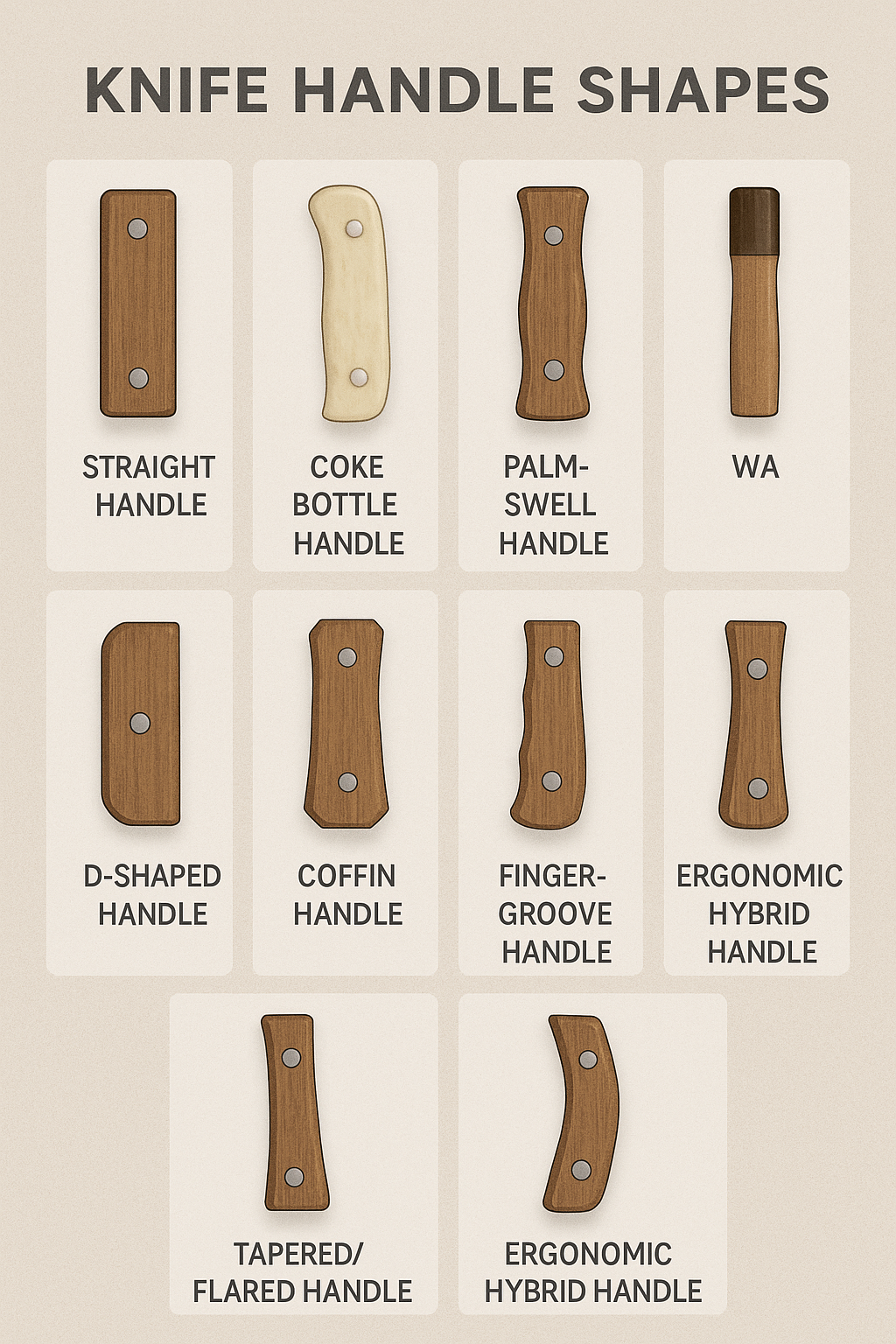

1. Straight Handle

The straight handle is simple, linear, and widely adaptable. It doesn’t favor any one grip style, which makes it suitable for general-purpose use. However, it offers little built-in grip support, relying instead on friction and hand strength.

Best for: Everyday carry (EDC), utility knives, or when you want users to have freedom of grip.

2. Coke Bottle Handle

This classic shape flares out at both ends and narrows in the middle—like an old glass Coke bottle. It naturally fits the curves of the palm, offering a more ergonomic and secure grip, especially during repeated use.

Best for: Outdoor, hunting, or skinning knives; anywhere grip retention and comfort are key.

3. Palm-Swell Handle

The palm-swell design builds on the Coke bottle idea with an even more pronounced middle section. It fills the hand more completely, improving control and reducing fatigue. Many survival and bushcraft knives use this shape to support long cutting sessions.

Best for: Bushcraft, camp, or field knives.

4. Pistol Grip Handle

Angled downward at the butt like a pistol, this handle puts the wrist in a more natural alignment, increasing leverage and reducing strain. It’s great for push cuts or downward chopping motions.

Best for: Butcher knives, cleavers, or tactical fixed blades.

5. Wa Handle (Octagon/Oval)

Common in Japanese kitchen knives, the Wa handle is traditionally lightweight and non-contoured. The octagonal or oval profile allows for fine grip control, and it's designed for blade-heavy balance.

Best for: Precision kitchen tools or chef knives where finesse is key.

6. D-Shaped Handle

Popular in traditional Japanese knives, the D-shape has a rounded outer side and a flatter inner side that rests against the palm. It locks into the hand naturally but is often made for right-handed users (and can feel awkward for lefties).

Best for: High-end Japanese culinary knives or single-user applications.

7. Coffin Handle

Angular, symmetrical, and tapering slightly at both ends, the coffin handle is a nod to traditional and historical knife styles. It provides a stable, no-slip grip with a vintage aesthetic.

Best for: Bowies, daggers, and period-inspired designs.

8. Finger-Grooved Handle

Finger grooves offer predefined slots for each finger, helping prevent slippage and ensuring consistency in grip. The downside is that it can feel awkward or even uncomfortable if the user’s hand doesn’t match the design exactly.

Best for: Task-specific knives or knives designed for a particular user or hand size.

9. Tapered/Flared Handle

These handles narrow or widen toward the butt end, depending on function. A flare at the bottom helps keep the hand from slipping, especially in pull cuts. Tapered handles can also improve visual flow and weight distribution.

Best for: Skinning knives, draw knives, or any tool requiring grip security.

10. Ergonomic Hybrid Handles

Many modern knives use hybrid designs—blending elements of Coke bottle curves, pistol grip angles, and palm swells—to create ergonomic shapes tailored for specific uses. These are often designed using CAD software or field-tested with prototypes.

Best for: Custom or production knives where comfort and performance are top priorities.

Final Thoughts: Designing for the Hand

When choosing or designing a handle shape, ask yourself:

-

What tasks will the knife perform?

-

Will it be used in wet, cold, or gloved conditions?

-

Is it a working knife, a showpiece, or both?

A good handle disappears in the hand. It doesn’t demand attention—it enhances control, improves safety, and turns a sharp blade into a precision tool.

Whether you’re crafting your first knife or your fiftieth, handle design is a chance to blend form with function. Test your shapes, tweak your contours, and keep refining. Because when a knife feels right in the hand, it performs better in the field—and that’s what great knifemaking is all about.